In addition to measuring temperature, thermistors can be used for surge protection, flow detection, and more.

Thermistors are widely used as the sensing element of a temperature sensor, and rightly so. They are easy to implement, they have a little variety when you are shopping for one (being available in varying levels of accuracy and form factors), and they have a number of other uses if one is so inclined.

For example, in addition to temperature measurement, they can be used for surge protection, liquid level or flow detection, time delay, and temperature compensation. Once thermistor technology is understood, these applications seem intuitive, but these devices are still somewhat obscure, even in the passive electronic components industry.

The name thermistor is simply a combination of the words “thermal” and “resistor.” This refers to a device that has a resistance value that varies with temperature. Commonly, the resistance has an inverse relationship with temperature, resulting in the negative temperature coefficient (NTC) appellation. Having said this, positive temperature coefficient (PTC) thermistors are also available.

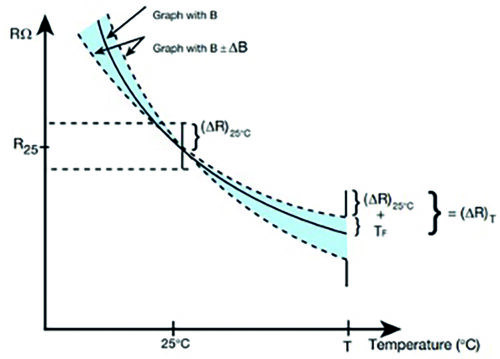

Each thermistor will have a characteristic Resistance vs. Temperature curve based on an intrinsic property known as beta (β), which is—by far—the most critical parameter associated with the device. By applying a known current to a thermistor and observing the resultant voltage, we can determine the temperature using a look-up table based on the R vs. T curve (and Ohm’s law, of course). Other parameters like beta tolerance and the resistance value at 25°C are also important and may need to be finely tuned for an application, but typically at a premium.

When the accuracy of the resistance value is not paramount, we can start using thermistors for some additional applications by exploiting the fact that they respond quickly to temperature changes and that resistors heat up with increasing current. A thermistor subjected to a surge current will heat up and then cool off as the surge subsides. This means the thermistor will limit surge currents in the beginning because the thermistor is “cool” and will have relatively high resistance. It will then let more current pass as it heats up to a more usable value. Expanding on the high resistance to low resistance theme, thermistors can be used as a time delay or current limiter in charge control applications where IC solutions are not needed. The drawback of using thermistors as a circuit protection or charge control device is, of course, efficiency. In ambient conditions, the thermistor in these circuits will be drawing power constantly.

In the case of liquid level/flow measurement, the set up would be very similar to temperature measurement. What is good to note here is that lead-less form factors of these devices exist for unique size constraints, hybrid applications, or if a low-profile array is needed, perhaps in a power electronics stack. Typically, thermistors are packaged in radial leaded or SMT chip form factors, but there are options for niche projects. As wide band gap semiconductors continue to gain traction, accurate and speedy temperature measurement capability will be required, and thermistors will be there.