Autonomous mobile robots and semi-autonomous cobots are candidates for supercapacitors.

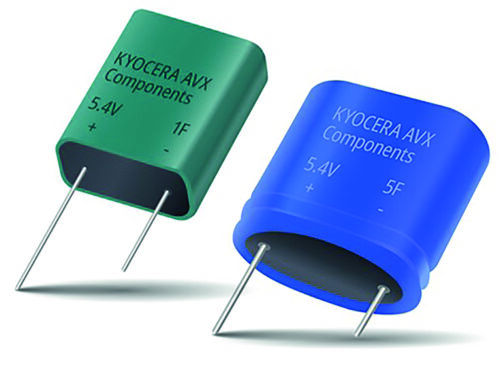

Commonly known as supercapacitors, electrochemical double-layer capacitors (EDLCs) are still relatively new to the electronics industry. Only recently have AEC-Q200 qualified supercapacitors entered the scene and only a few suppliers provide them. Determining their viability for a design will require research on EDLC technology, but looking at a few examples can help.

Warehouse robots, autonomous mobile robots, and semi-autonomous cobots (collaborative robots) come to mind as candidates for supercapacitor use for two main reasons: (a) they typically have a docking station for charging and (b) they frequently have tasks requiring short bursts of increased power to lift/move heavy loads.

Supercapacitors have an advantage over batteries with respect to specific power, meaning they can discharge massive amounts of current with no penalty on lifetime or reliability. They’re also unlike batteries in that their charge/discharge cycles approach 1 million cycles as opposed to the thousands or possibly tens of thousands found in batteries. By comparison, if a robot needs to operate a long time remotely, batteries may offer the best solution.

An analogy that might help is the use of nitrous oxide in racing cars and drag cars for added power. At a certain distance, the weight of the nitrous (supercapacitor) would not be as efficient as having a larger gas tank (battery). We could extend this analogy to supercapacitor ESR (equivalent series resistance) contributing to the counterpart of a lower brake horsepower value. Supercapacitor modules are typically balanced with resistors, thereby adding to ESR. If the design is not too strictly weight- or size-constrained, adding a supercapacitor module to supplement the battery on peak power operations will increase efficiency and extend battery life. Similarly, for robotic applications relying on energy harvesting, supercapacitors are better suited to capturing spurious charge currents.

Another example application with implications for industrial automation robots exploiting the superior power performance of supercapacitors can be found in the kitchen. Restaurants and other non-residential buildings are charged by power companies on peak power demands. Supercapacitor banks can be used to turn on ovens, fryers, and burners during the day, while charging at night when power usage rates are lower. This leads to desirable cost savings for the business owner while also relieving strain on the grid.

The high current capability and high charge/discharge cycles of supercapacitors are key factors on design-in, so meeting a need for high-power demands increases viability for industrial automation.

One important point is for supercapacitor banks to be used only in environment that don’t stray too far from an ambient temperature of ~25°C. A common electrolyte used in supercapacitors is acetonitrile, which begins to boil at 85°C, although there are aqueous-based systems that push this to 95°C. Of course, the best design practice to stay as far beneath the maximum temperature rating of a component as possible and this is especially so for supercapacitors. A good rule of thumb for operating temperatures is that every 10°C below the maximum rated value will double the expected lifetime of the component.