Advanced capacitors can have a significant impact on system size, performance, and reliability.

Passive components have experienced a massive evolution in recent years, and the rate at which these technologies continue to advance is accelerating. Results include ever-smaller sizes and weights, along with improved individual part reliability and electrical performance. These advances have permeated virtually all capacitor offerings, but two specific capacitor technologies—multilayer ceramic capacitors (MLCCs) and polymer electrolytic capacitors—have achieved unrivaled progress. And since approximately 80% of the components on a printed circuit board (PCB) are passive, and a large percentage of these are capacitors, these advanced capacitors can have a significant impact on system size, performance, and reliability.

Capacitors

Modern integrated circuits (ICs) employ more transistors than older devices. They require power supplies with much higher currents and current transitions (di/dt) and, as such, higher capacitance IC power distribution networks to support these increased di/dt demands.

Higher capacitance power distribution networks can be achieved with smaller, higher density capacitors placed closer to the IC. This placement reduces the time needed for the capacitor to deliver current to the load and boosts effectiveness.

Smaller case size capacitors (e.g., 0402, 0201, 01005, and 008004) are available with multiple practical and low-cost attachment methods that allow them to (a) be placed in close proximity to the IC die and (b) optimize the circuit.

Multilayer ceramic capacitors

Advances in MLCC technology offer designers a high-capacitance alternative to traditional electrolytic capacitors. This results in the ability to deliver higher capacitance values, along with low ESR and ESL, in small packages. The same technology that enables a 100µF, 6.3V 0805 X5R MLCC also enables an ultraminiature 100nF 008004 MLCC. As such, MLCCs offer effective solutions that span the gamut from high-CV bulk capacitors to the microminiature MLCCs typically used in high-frequency filtering and decoupling applications.

Recent MLCC technology developments are the result of various factors, including ceramic material advances, improved thin metal electrode and ceramic layer processing technologies, and enhanced miniature stacking, dicing, and testing capabilities.

This combination of material advances, improved electrode and dielectric thickness control, and manufacturing capabilities results in MLCCs with a high capacitance per unit volume (high CV). For example, a cross section of a typical high-C/V 22µF 0402 MLCC could reveal 500 dielectric layers that each have a height profile that measures less than just one hundredth the thickness of a single human hair.

The process accuracy and control needed to make high-CV 0402 MLCCs also enables the development of ultraminiature case size MLCCs ideal for use in applications with stringent size and weight restraints, including smartphones, wearables, and other portable electronic devices.

A typical smartphone has more than 1,000 capacitors in it, and the total volume of those capacitors is roughly equivalent to that of a penny. But portable electronics manufacturers are always looking to reduce size and weight while maintaining or even increasing power. So, we conducted a study to evaluate the impact of MLCC case size on weight and PCB mounting area (see the table).

The first step in the PCB mounting area study was to calculate the area occupied by 100 0805 MLCCs mounted in a 10 x 10 array with 0.2mm spacing and to define that board area as 100%. We then placed 100 smaller case size MLCCs, ranging from 0603 to 008004, in a similar 10 x 10 layout with 0.2mm spacing and compared the resulting PCB areas. The benefits of miniature and ultraminiature case sizes were readily apparent, with the smallest case size (008004) MLCCs occupying just 4.2% of the area that the 0805 MLCCs occupied. The weight reduction benefits of the smaller case size MLCCs proved equally appealing, with the 008004 to 0805 case size comparison achieving an approximate weight reduction of 99.9%.

Other useful comparisons can be extracted from the table as well. For instance, if a design using 100 0603 MLCCs was retrofitted to use 0402 case size MLCCs, the manufacturer could achieve 54% board space savings or place 271 additional 0402 MLCCs in the same area that had been occupied by 100 0603 MLCCs.

However, it is important to note that miniature MLCCs with certain dielectrics can potentially exhibit instability in circuit. Tantalum polymer capacitors eliminate those concerns.

Tantalum polymer capacitors

Tantalum polymer capacitors are miniature bulk capacitors that are available in a variety of voltages, case sizes, height profiles, and quality levels, which supports maximum placement efficiency, and they also exhibit very low ESR and ESL. Key features include the fact that they exhibit approximately one eighth the ESR of standard MnO2 tantalum capacitors, and can therefore handle much higher ripple currents; also, they can exhibit ESL as low as 1nH. Tantalum polymer capacitors also exhibit improved energy density and virtually no aging, voltage bias, or temperature instability effects. These features provide designers with the flexibility to find reasonably sized bulk capacitors in case sizes as small as 0402 with height profiles as low as 0.55mm.

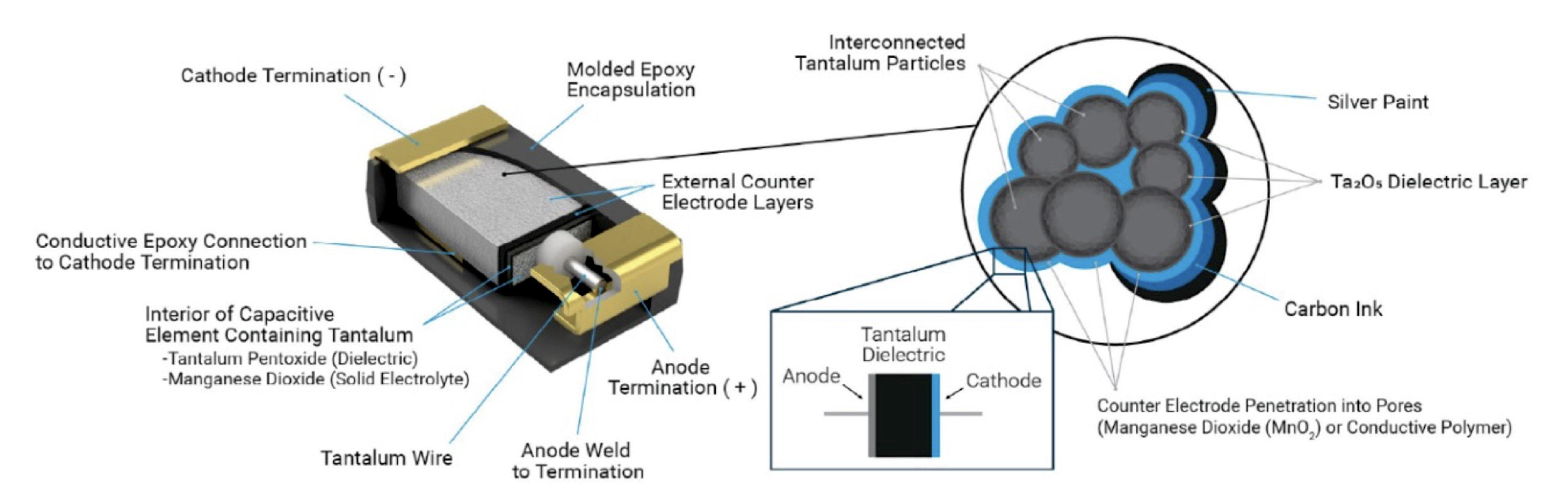

Tantalum polymer capacitors feature a conductive polymer in the cathode. They are formed by capping the tantalum anode wire with a porous pellet of tantalum powder, sintering that structure into a monolithic block to form a Ta2O5 dielectric, depositing a conductive polymer layer onto the monolithic block structure to reduce ESR, and some added processing.

Summary

Modern MLCCs and tantalum polymer capacitors exhibit parameters desired in future circuitry. Both deliver a variety of small, high-density capacitance solutions that support multiple practical and low-cost attachment methods and can be placed close to ICs to optimize the circuit.

Advanced MLCCs deliver high-CV, low ESR, and low ESL, easily accommodate mounting configurations spanning embedded to board mounted, and are ideal for high-frequency IC decoupling and filtering applications.

Advanced tantalum polymer capacitors are available in miniature packages that deliver low ESR and ESL and effectively address gaps in the existing bulk capacitor market.

Continued size reductions are expected for both types, with MLCCs progressing down a known path all the way down to 008004 case sizes and tantalum polymer capacitors continuing towards smaller case sizes with the potential for added disruptive case size evolution.