MEMS-based precision timing technology boosts automotive safety and reliability.

by Sumeet Kulkarni, Director of Product Marketing, Automotive at SiTime Corporation

As the automotive industry evolves toward more advanced technologies, embracing electric vehicles (EVs) and automated driving, precision timing is becoming critical to ensuring the safety, reliability, and performance of these increasingly complex systems.

SiTime’s Chorus automotive clock generator, a precision timing solution featuring a fully integrated clock system-on-a-chip (ClkSoC), is designed to address the unique challenges faced by automotive engineers with the rise of software-defined vehicle (SDV) technology.

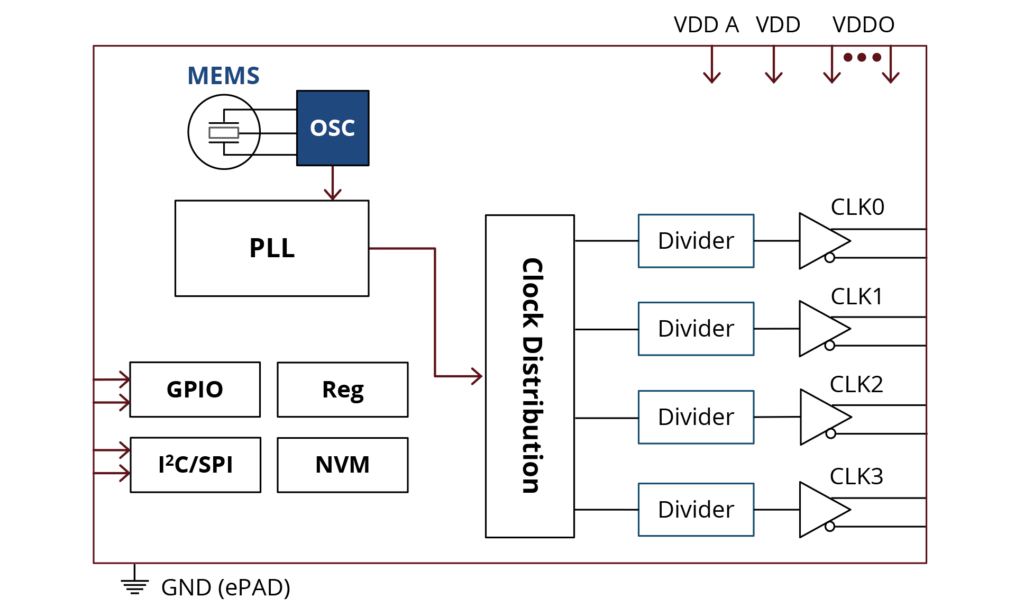

A Chorus automotive clock generator integrates a microelectromechanical system (MEMS) resonator, oscillator, phase locked loop (PLL), and advanced safety mechanisms into a single compact package, reducing cost and complexity, enabling enhanced diagnostics, and improving safety performance for automotive systems. With built-in FailSafe technology, Chorus clock generators provide the critical diagnostic capabilities necessary to meet functional safety requirements of automotive electronic systems, including those specified in the ISO 26262 standard.

Why timing matters

Increasingly autonomous vehicles have shifted the focus of automotive design from traditional hardware to a highly sophisticated integration of sensors, electronic control units (ECUs), and communication systems running millions of lines of code. Today’s technology-laden SDVs process enormous amounts of real-time data—sourced from cameras, radar, Lidar, and myriad sensors—that must be managed with high precision and minimal delay.

Precision timing is central to these systems. From advanced driver assistance systems (ADAS) to in-vehicle infotainment, each subsystem relies on precise synchronization of digital components to function reliably. If a timing component fails or is even slightly out of sync, the vehicle’s ability to make quick, autonomous decisions and respond to its environment is compromised, potentially putting lives at risk.

This is where Chorus clock generators become indispensable. As automotive systems continue to advance, their timing solutions must not only deliver precision but also provide robust fault detection and diagnostics to prevent failures before they occur. Chorus automotive clock generators are designed to meet these demands head-on.

Tackling timing challenges

Chorus clock generators, with real-time fault monitoring, significantly reduce the fault-tolerant time interval (FTTI)—the time it takes for a system to detect and respond to a fault. While traditional quartz-based systems may take milliseconds to identify a failure, Chorus can alert the system to a timing fault in microseconds, bringing the vehicle into a safe state almost instantaneously.

This rapid detection is critical for meeting the high Automotive Safety Integrity Level (ASIL) functional safety ratings required for ADAS central computing modules. These systems must maintain safety even in the event of a malfunction, and Chorus provides the diagnostic capabilities necessary to ensure compliance with stringent automotive functional safety requirements.

Simplifying clock trees

Traditional automotive clock networks often rely on standalone oscillators paired with external quartz resonators. These configurations are prone to issues such as impedance mismatching and noise interference, making them less than ideal for the highly synchronized systems in modern vehicles. Furthermore, these designs require multiple components, increasing the overall complexity and size of the circuit boards.

Chorus clock generators streamline automotive clock tree designs by consolidating multiple timing functions with a single clock chip. A single Chorus clock generator can replace up to four differential or eight single-ended standalone oscillators, significantly reducing the timing footprint on the circuit board by as much as 50%. This streamlined approach not only saves space but also eliminates the impedance and noise issues associated with external quartz resonators.

Additionally, each clock output in a Chorus-based system is individually programmable, allowing engineers to customize the timing behavior for specific system needs. Whether it’s managing electromagnetic interference (EMI) or fine-tuning phase shifts to accommodate long circuit board traces, Chorus provides the flexibility and efficiency needed for today’s complex automotive designs.

Reducing Failure Rates and Enhancing Safety

Many legacy clock generators focus primarily on detecting external quartz resonator failures, but this leaves a large blind spot in the rest of the clock signal chain—components such as oscillators, phase-locked loops (PLLs), and output drivers.

Chorus clock generators, however, monitor the entire signal path—from the MEMS resonator to the output pin, and even the power rails and chip temperature. This end-to-end, continuous monitoring ensures that potential faults are identified and addressed before they can cascade into system-wide failures. Moreover, this comprehensive fault coverage can be tailored for each clock output, providing engineers with greater control over the system’s functional safety.

Chorus fault detection goes even further by alerting the system to clock-related faults within microseconds, which is up to 1,000 times faster than traditional solutions which would detect clock failures only after they have caused more widespread downstream failures. This faster response time enables automotive systems to return to a safe state more quickly, reducing the risk of catastrophic failures and providing automotive engineers with more room to manage their overall safety budget.

Harsh environments

Automotive systems must operate under extreme temperature conditions. Chorus clock generators are built to withstand these temperature extremes. They are designed to operate reliably across a wide ambient temperature range, from -40°C to +125°C, making them ideal for harsh environments and simplifying thermal designs of high-performance computing systems. With superior thermal stability and resistance to shock and vibration, Chorus is well-suited to the demanding requirements of modern automotive systems.

Future proofing

Chorus clock generators are future-proofed to support the ongoing transition to zonal architectures. Their high-frequency stability, low jitter, and programmable flexibility make them an ideal fit for both the domain-based systems of today and the zonal architectures of tomorrow. As vehicles become more intelligent and connected, Chorus will play a key role in ensuring that these systems operate smoothly and safely.

Driving innovation

Chorus clock generators are playing a key role in advancing precision timing technology for SDVs. By offering a fully integrated clock solution with FailSafe technology, Chorus enables faster fault detection, simplifies clock tree architectures, and provides robust performance in extreme environments.

Whether in ADAS, autonomous driving, or the infotainment systems of electric vehicles, Chorus is paving the way for safer, smarter and more reliable automotive technologies.