Switches are ubiquitous, so why do so few of us use the correct terminology?

Even though their underlying technologies are more than 100 years old, electromechanical switches continue to permeate today’s electronic products. For example, I just looked at the spiffy new RIGOL DS1054 oscilloscope sitting on my desk (“my precious”) and counted 39 pushbutton switches on the front panel alone.

Yes, we could use touch screens to replace many switch operations, but there’s something satisfying about the tactile feedback provided by honest-to-goodness electromechanical devices, which are more rugged and reliable in hostile environments like industrial settings.

What is a switch?

In electrical engineering, the term “switch” refers to an electrical component that can disconnect or connect a conducting path in an electrical circuit, thereby interrupting the electric current or diverting it from one conductor to another.

Switches come in a wide variety of shapes and sizes, from the knife switches favored by Igor and Frankenstein (“It’s alive! It’s alive!”) to magnetic switches to mercury tilt switches. As fate would have it, mercury tilt switches are one of the few switches that don’t bounce, which is ironic since so few of us use them in the first place (see also my column on switch bounce and debounce in the July/August issue of DENA).

Switches may be operated by hand, automatically operated (actuated by machine motion, e.g., by a limit switch), or process operated (actuated by physical changes in some process. e.g., temperature, pressure, humidity, level, flow, pH level).

Poles and throws

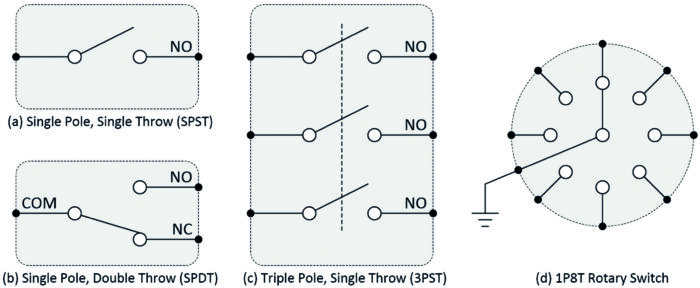

The term “poles” refers to the number of electrically distinct switches that are controlled by a single actuator. The term “throws” refers to the number of separate wiring paths (other than “open”) that are associated with each pole.

In the case of toggle switches, I tend to think of the contact connected to the fixed side of the actuator as being the pole, and the contact associated with the moving side of the actuator as being the throw. (In this context, the term “actuator” refers to the part of the switch to which an external force is applied to operate the switch, for example, a lever, rocker, knob, or button.)

Single-pole, single throw (SPST) switches, particularly pushbutton switches, are typically “open” (not connected) by default, so their throw contacts are referred to as being normally open (NO), but normally closed (NC) versions are also available. In the case of single pole, double throw (SPDT) switches, the common terminal is usually annotated as “COM.”

Pushbutton switches are commonly of the “momentary” variety, which means they are active only while the pushbutton remains pressed. However, “latching” versions—push once to activate and push again to deactivate—are also available.

In the case of more complicated switch configurations (typically anything more than single and double poles and/or throws), such as multi-throw rotary switches, it’s common to start using numbers like 1P8T (one pole, eight throws).

Make and break

Consider an SPST switch. When this switch is in its OFF state, it is said to be “open” because the effect is the same as if the switch were to be removed from the circuit leaving an “open circuit,” which refers to an electrical circuit that is not complete. By comparison, when the switch is in its ON state, it is said to be “closed,” in which case the effect is the same as if the switch were to be replaced by a piece of conducting wire.

It’s also common to use the term “make” (i.e., “making the connection”) to refer to closing the switch, and “break” (i.e., “breaking the connection”) to refer to opening the switch.

In the case of a switch with more than one throw, like an SPDT toggle switch, for example, then the most common type is classed as break-before-make (BBM). This means the moving contact breaks the existing connection with the current throw before making a new connection with the new throw. These are also known as “non-shorting switches.”

Although they are less common, it’s also possible to obtain make-before-break (MBB) switches in which the moving contact makes connection with the new throw before breaking its connection with the existing throw. These are also known as “shorting switches.”

SPCO and DPCO

When we think of an SPST switch, we may also think of it as operating in an ON-OFF manner. In the case of a SPDT switch, we might describe this as operating in an ON-ON manner.

There are also toggle and rocker switches that are like SPDT switches—including using identical schematic symbols—except they have three positions for the lever (rocker). These are known as single pole, changeover (SPCO) or single pole, center off (SPCO) devices. Similarly, there are double pole, double throw equivalents called double pole, changeover (DPCO) or double pole, center off (DPCO). We may think of these switches as operating in an ON-OFF-ON manner.

Who do you trust?

There are, of course, many purveyors of switches. One of my favorites is C&K (ckswitches.com), which recently became part of Littelfuse (littelfuse.com), not least that the company was formed by Charles A. Coolidge, Jr. and Marshall Kincaid in 1957, which is the same year I decided to grace this planet with my presence.

One reason I favor C&K is that they offer 55,000+ base products and support 8,500,000+ switch configurations and combinations. Their strength is their ability to offer a full range of catalog products that can be rapidly customized into tailored solutions for their clients, of which I’m one.

The future is now

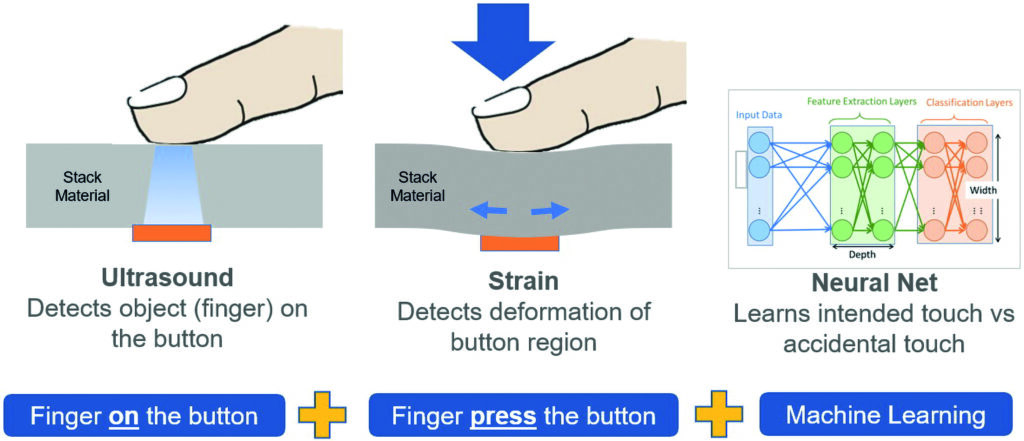

Will we always be chained to electromechanical switches? Probably not. For example, the folks at UltraSense Systems (ultrasensesys.com) have developed an ultrasonic sensor that makes a grain of rice look large by comparison.

This sensor can be mounted behind, or embedded in, a control surface of any practical thickness, because its ultrasonic signal can penetrate anything from hard plastic to stainless steel up to 5mm and 2mm thick, respectively.

In addition to the ultrasonic transceiver, four tiny piezo strain gauges allow this little scamp to detect deformations as small as 100nm in the surrounding material. It also boasts a neural touch engine (NTE) that supports native machine learning (ML) that can be taught to differentiate between intended vs. accidental touches. It probably goes without saying that the one thing this little beauty doesn’t give us is any form of switch bounce.

As always, we certainly do live in exciting times.