Meet the pneumatic equivalent of an electronic bench power supply.

by Rick Renfroe, Business Development Manager at Proportion-Air

As its name implies, DENA is all about the design of electronic systems. However, such systems rarely operate in isolation; much of the time they interact with the real world, engaging with electromechanical, hydraulic, and pneumatic systems to get the job done.

In the case of electronic-pneumatic systems, for example, a fundamental aspect of controlling these applications is when an electro-pneumatic regulator receives an electronic input signal from a programmable logic controller (PLC) or a computer with an I/O card, and it adjusts its pneumatic output to proportionally match the input signal.

In the design and testing of these systems, electronic design and test engineers are familiar with the concept of a bench power supply that can be used to specify the desired voltage, set the maximum current that can be supplied at that voltage, and then monitor and display the actual values seen when powering the design under test (DUT).

But what happens when it comes to verifying the operation of the pneumatic portion of the system? This has traditionally involved a plethora of bulky instruments, probes, test leads, and wires that could send anyone with OCD clamoring for their anxiety meds. In addition, most pneumatic test equipment isn’t tremendously portable, so the work must come to it.

In many cases, it would be advantageous to have the pneumatic equivalent of a bench power supply. Something that allowed the user to specify the desired pressure, set the maximum air flow that can be supplied at that pressure, and then monitor and display the actual values seen when powering the design under test (DUT).

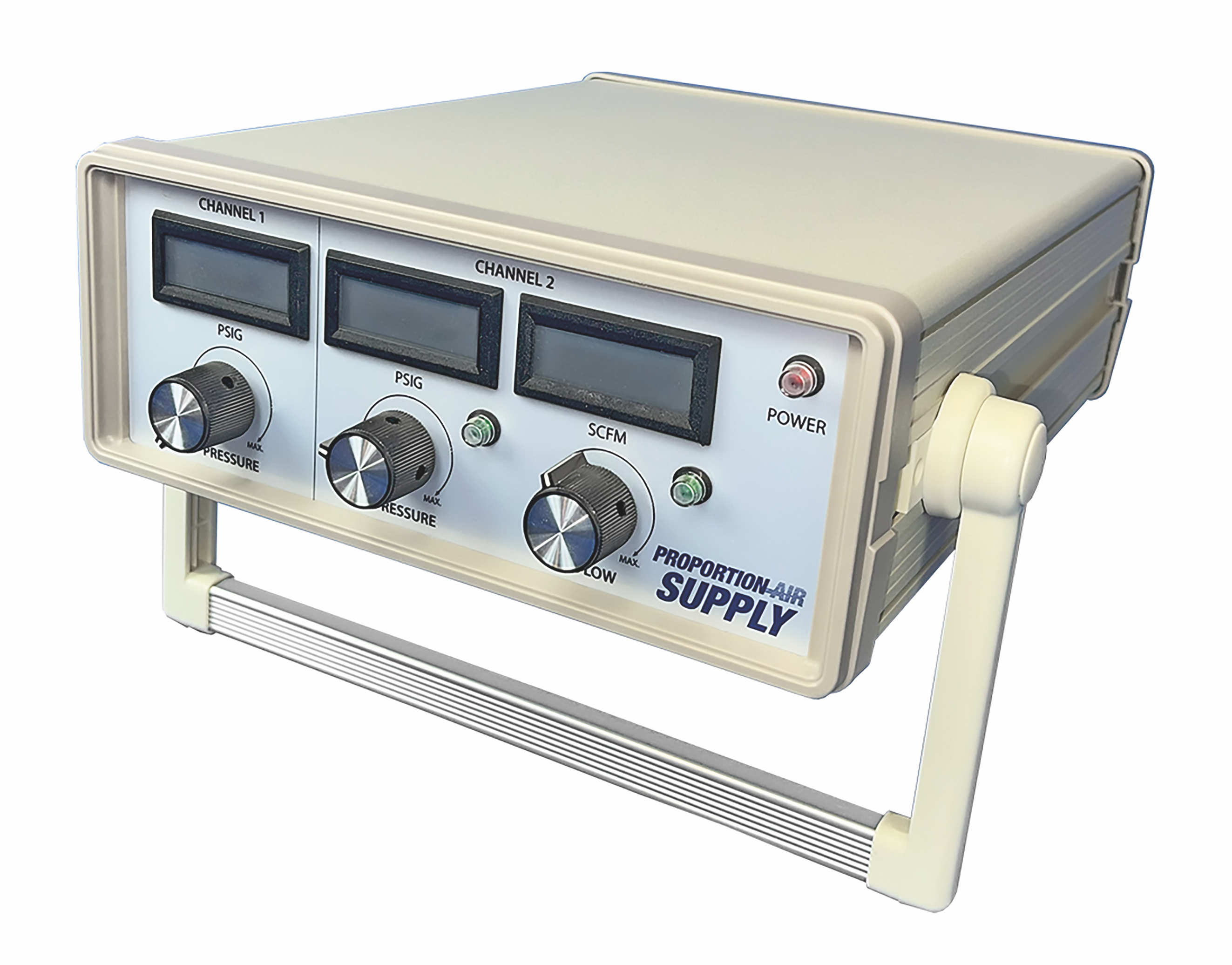

That’s why we’ve introduced the Proportion-Air Supply. This new benchtop device can be used for developing, testing, and diagnosing pneumatic equipment. Executing burst tests, creating flow curves, and calibrating air-piloted regulators are just a few of the applications it can be used for.

The all-in-one nature of this unit replaces the need for separate regulators and flow and pressure gauges attached to needle valves. It includes two channel options, one output channel is solely for pressure regulation, which is ideal for simple testing processes, while a second channel regulates flow and pressure at the same time, like the way in which a variable DC power supply regulates voltage and current.

Digital panel meters show the pressure or flow being achieved, while LEDs indicate when the desired pressure or flow has reached its setpoint. In addition, the portable nature of the unit allows you to take this portion of your benchtop testing system with you in the field (as long as you can access an electrical outlet and an air or pneumatic source, of course).