Using advanced high voltage meters improves accuracy and offers a portable, simplified solution.

When working with test and measurement equipment to calibrate high voltage systems, electrical and test engineers typically use external probes such as high voltage dividers. However, these instruments are prone to errors that can lead to imprecise readings. This article describes an alternative approach to measuring high voltage systems that employs advanced high voltage meters.

Measuring high voltage systems

High voltage applications span numerous industries, from high-tech, medical, and automotive, to industrial manufacturing, research labs, aerospace, and many more. The high voltage systems used in these applications include:

- Switchgear

- Switches

- Power transformers

- Instrument transformers

- Reactive power equipment

- Insulators

- Control equipment

- Relay panels

Measuring high voltage systems during design, manufacturing, and in calibration labs is essential for meeting various global reliability and safety standards, as well as manufacturers’ warranty requirements. The high voltage test and measurement instruments used for this calibration include:

- Meters

- Voltage dividers

- Power supplies

- Signal sources

- RF power amplifiers

- Hipot testers

- Oscilloscopes

This article focuses on two such high voltage test and measurement instruments: meters and voltage dividers.

Voltage dividers

Voltage dividers are external probes commonly used to measure higher voltages. For example, a 100:1 voltage divider allows an instrument with a 1kV (max) input to measure an applied voltage of up to 100kV. Composed of many carefully matched resistors, a voltage divider will (theoretically) eliminate errors from self-heating or other factors that affect the resistor string in a uniform fashion. However, there remain a number of contributing factors to error and uncertainty when using a voltage divider, including:

- Resistance variation from one resistor to another

- Variations (although minor) in temperature coefficients

- Electromagnetic effects

- Capacitance effects

- Variations in meter input impedance, which necessitates it must be calibrated with the meter

Advanced high voltage meters

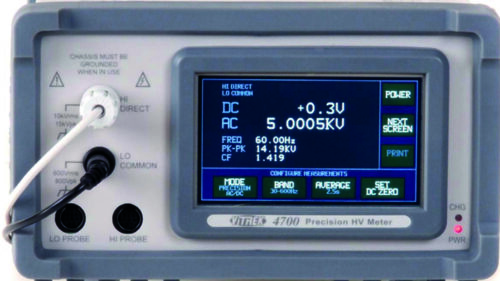

Today’s advanced high voltage meters, such as the Vitrek 4700 Precision HV Meter, allow test engineers to directly measure voltages up to 10kV (10m kV DC or RMS AC) without using external probes. This meter offers performance that rivals traditional high voltage reference dividers but—unlike using a divider—it provides instant and direct high voltage measurements in a portable bench-top enclosure. This meter is capable of meeting the following high voltage specifications:

- Base accuracy: 0.03% DC, 0.1% true RMS plus limitations and adders (no range adder needed): Maximum voltage: 10kV DC, 10kV AC RMS

- Impedance: 110 MΩ

- Ranging: None

- Noise Floor: 30mV

- Frequency response: 0.01Hz to 600Hz

- Offsets: Up to 800V

- Differential measurements if two external probes are used

To extend high voltage measurements beyond 10kV up to 150kV, SmartProbes can be added to the 4700. Unlike voltage dividers that must be calibrated with the meter, these probes store their own calibration data, which is downloaded when plugged into the meter.

Conclusion

The typical approach of employing a voltage divider network when calibrating high voltage systems comes with drawbacks, such as introducing error-producing effects like self-heating, capacitance effects on AC measurements, and electromagnetic effects. In contrast, using advanced high voltage meters improves accuracy and offers a portable, simplified solution.