Using an enhanced non-contact methodology to make skin thermometry more accurate.

In today’s modern society, we are now much more aware of the need for a better understanding of our health and wellbeing. Body temperature is one of the essential parameters via which assessments can be made, and this article discusses the most effective ways of doing this to a high degree of accuracy. In particular, we look at the role consumer electronics is set to play.

The capturing of skin temperature data using either items of portable equipment (like smartphones) or wearables (such as fitness trackers, earbuds, or smart watches) has numerous tangible benefits. It can potentially provide early indications of infection as well as uncovering underlying health conditions. Furthermore, if carried out regularly throughout the day, temperature measurements could help with fertility tracking, stress monitoring and analysis of circadian rhythms (so sleep patterns can be improved). This fits in with the growing popularity of wearables—presenting the opportunity for data to be acquired on a continuous basis (or at least for a large proportion of the time) as the person will already be wearing such technology for another purpose.

Different approaches to temperature measurement

Two basic methodologies exist for gaining temperature data. These rely on contact and non-contact arrangements. Thermometry based on direct contact is prone to inaccuracies due to difficulties keeping a stable, good quality thermal interface connection between the sensor and the subject’s skin. If the sensor is not in proper thermal contact with the skin, then the data quality derived will be poor.

In contrast, non-contact temperature measurement does not experience that problem. Here, energy emitted from the target object at far-infrared (FIR) frequencies (in the 2µm to 14µm) wavelength region) is detected. From this, the actual temperature of the target object can be calculated. When dealing specifically with human thermometry, there are places on the body (referred to as proximal points) where skin temperature can be correlated to core body temperature.

Proximal temperature measurement points include the forehead, the corner of the eye next to the nose, inside the ear, and behind the ear. If non-contact measurement is performed at these points, then core temperature extrapolation is possible.

Applying temperature measurement to wearables and smartphones

Key engineering challenges must be overcome if skin thermometry is to be used in a wearable/portable equipment context. First, temperature sensing devices must be small enough to fit into electronic designs that have acute size constraints without compromising performance. Second, these devices’ power consumption figures need to be kept as low as possible, so equipment battery life is not shortened by their use.

An issue that sensor miniaturization brings with it is that, as devices get smaller, it becomes more difficult to maintain their thermal stability, which consequently impacts on their accuracy levels. Generally, FIR temperature sensor accuracy is influenced by thermal gradients caused by other sources of heat within the vicinity. Unfortunately, smaller sensor packaging only makes matters worse, with devices being more seriously affected.

It must also be recognized that integration into wearables/portable equipment is likely to have detrimental thermal implications too. For example, due to there being very limited board space available, the temperature sensing device might end up being placed close to a microprocessor that is generating relatively large amounts of heat.

Effective mechanisms are needed to compensate for the presence of unwanted parasitic signals caused by external heat sources, otherwise acquired temperature data will not be of real value. Greater thermal stability can be attained through placing sensor elements within large metal can packages. These offer substantial thermal mass and elevated thermal conductivity properties. However, arrangements of that kind will clearly not work in system designs where space is limited.

By carrying out extensive modeling and characterization work across a multitude of different scenarios, then applying sophisticated compensation algorithms, the outputs from compact FIR sensors can be augmented. The upshot is significant signal thermal stability improvements.

Compact, thermally-stable, and power-efficient non-contact thermometry

The engineering team at Melexis appreciated from an early stage that inclusion of non-contact measurement in consumer electronic products would become increasingly commonplace. This was the motivation behind the development of the MLX90632, which is already being incorporated into smart watches and smartphone handsets from several of the world’s most high-profile consumer technology brands.

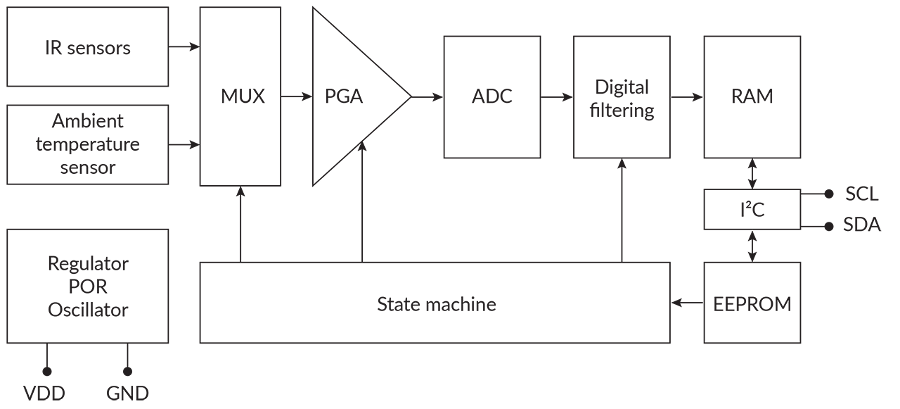

This factory-calibrated FIR sensor device features advanced MEMS thermopile technology. Dedicated active compensation algorithms safeguard against the effects of external thermal disturbances. Once temperature measurements have been taken by the thermopile, the signal is amplified, translated into digital form, and then filtered. The device’s I2C bus permits subsequent interfacing with the system microcontroller unit (MCU).

Commercial and medical grade versions of the MLX90632 are available, with the medical grade version delivering ±0.2°C accuracy over object temperatures spanning from 35°C to 42°C (meaning that the human body temperature range is fully covered). This accuracy satisfies both FDA and CE medical equipment guidelines.

A simple-to-use software driver allows the duty cycle to be set as power budget requirements dictate. For example, at a rate of one measurement per minute, the MLX90632 draws only 100μW. Compactness is another advantage, with the surface-mount devices housed in QFN packages (dimensions being just 3mm x 3mm x 1mm).

As the MLX90632 relies on FIR (2µm to 14µm) operation, there is no possibility of near-infrared (NIR) emissions interfering with the results obtained. For instance, it may be that equipment is simultaneously taking photo-plethysmography (PPG) measurements (for heart rate monitoring) using NIR in the 600nm-900nm range, but this does not pose a problem.

Conclusion

Accurate temperature measurement is a desirable function that will drive wearable/portable hardware sales; however, exacting operational demands must be met. A thermometry solution which combines medical-grade accuracy, compact form factor, and assured thermal stability is thus mandated. The latest sensor innovations are making this a reality. Not only are these devices opening up new prospects in the consumer electronics sector, but they are also highly suited to use in clinical thermometry and diagnostic tools.