As industrial aesthetic and ergonomic standards increase, buyers are being offered new generations of customizable enclosures which can be ordered in small volumes.

Advanced industrial manufacturing and production facilities have always required customized systems to ensure optimum performance and productivity. IIoT makes that even more important because its empowering wealth of data enables greater real-time optimization.

So, the electronics controlling modern technical facilities must be cutting edge. This places greater demands on the system’s human- machine interfaces which, in turn, raises the stakes for the enclosures housing the HMI electronics.

Put simply, advanced systems need leading- edge HMI technology, housed in ergonomic enclosures that can cope with industrial settings but remain comfortable to view and operate.

These days, enclosures must also look the part. Aesthetics have become more important in an age when clean rooms and robotics are increasingly superseding traditional 20th century factories.

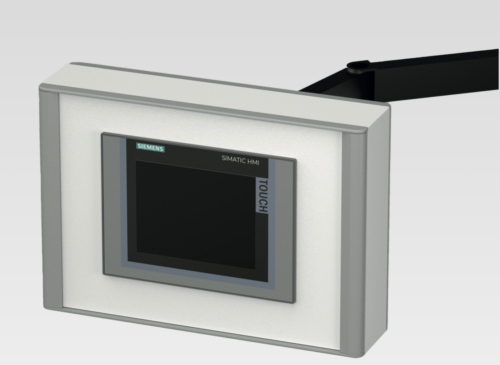

The latest HMI enclosures have been designed with customization, versatility and elegance at their heart. They are exemplified by Metcase’s new Technomet-Control VESA-mount enclosures for standard touch screens, displays and panel PCs. These housings represent a modern, cost-effective alternative to traditional wall- and pole-mount enclosures.

The design ethos was simple. Metcase wanted to create a fabricated aluminum HMI enclosure manufactured to the same fine tolerances as molded plastic housings. Diecast front and rear bezels fit flush with the main case body, enhancing the aesthetics. Snap-on trims hide the assembly screws.

The range has been designed principally for Siemens TP screens—KTP400 to TP1200—but will also suit Beckhoff and B&R displays. The rear features a standard VESA MIS-D 100 mounting for a control arm or wall bracket. The enclosures can also be mounted on poles or masts 1.97” diameter or larger. Applications include industrial machine control, factory processing, security systems, test and measurement, point-of-sale, IIoT and detection equipment.

The enclosures are easily manufactured in bespoke heights, widths and depths thanks, in part, to the way the bezels fit together. After that, it’s simply a matter of machining apertures and adding optional fixings and inserts (every panel has an M4 earthing pillar). Legends and logos can be printed digitally, reducing set-up costs.

Custom colors beyond the standard traffic gray A and traffic gray A/traffic white can be specified. This flexible manufacturing system lets Metcase offer these customized enclosures in comparatively small volumes—as few as 10 or 20 units—making them a viable option for niche applications. The 3.74” deep enclosures are available in four plan sizes from 9.06” by 7.09” to 16.54” by 11.81”.

For larger displays, designers can specify enclosures such as Rolec’s profiPANEL (IP 65) which is designed to make customization simple and cost-effective. It does so by moving part of the customization phase from the end of the process to the beginning.

Ordinarily, a customer would select an off-the-shelf enclosure and then specify customization processes such as machining of apertures, painting (or powder coating) and printing.

However, profiPANEL features a profile-based design so enclosures can be specified in any plan size from 5.90” by 5.90” to 31.50” by 31.50” (any size between) and in nine possible depths from 2.36” to 11.81” by combining two widths of aluminum profile (2.36” and 3.54).

This ensures enclosures remain cost-effective—even more so by specifying the profiPANEL standard version available in four off-the- shelf plan sizes, all 3.54” deep. The result is a robust, attractive and practical enclosure offering almost edgeless flush mounting of a front plate. Access for inspection and maintenance is via a lockable hinged door.

It pays to get expert advice from a specialist manufacturer, ideally a single-source supplier who can carry out all the customization work in-house. This ensures one supplier is fully accountable for the entire process, ensuring quality and saving time, money and administration.

It’s worth consulting an enclosure manufacturer early, ideally before component layout has been finalized. This can result in specifying a smaller enclosure than perhaps initially envisaged, enhancing device appeal and reducing manufacturing costs. It can help to identify design opportunities not previously considered.