Timur Uludag, Product Manager for the MagI3C Power Division at Würth Elektronik.

Transmitting data over cables in industrial applications comes with the challenges of a high transient voltage environment and high EMC interference.

Industrial environments like warehouses, filling plants, rolling mills, and conveyor belt systems all have one thing in common: they are characterized by a high degree of automation. Temperatures, voltages, speeds and other physical variables are measured by sensors “in the field” and forwarded to a central location. Here, actions are initiated that, for example, reduce the speed of a motor to decrease a temperature reading that is too high. Due to the large space these systems occupy, there can be tens of meters of cable between a sensor and the central control unit.

Interference-free data communication and personal safety are two major challenges for electronics in this type of industrial environment. Strong electromagnetic fields, surge voltages, transient voltages and high EMC noise are commonplace. If, for example, the communication line is laid unfavourably close to a control line of a frequency converter, the pulses will be capacitively coupled and the signals in the communication line will oscillate with the pulse pattern of the frequency converter.

These disturbances can quickly reach a level where significant malfunctions occur and even personal safety can be compromised. For example, when measuring the temperature of a motor using a thermocouple, voltages in the millivolt range are generated. If these voltages are now transmitted over a cable length of several meters to a central control unit that refers to a different ground potential, the measurement signal will be distorted by the potential differences.

Functions of an isolator

Clustering the described phenomena, the following four challenges emerge:

• A safety barrier between hazardous voltages and users.

• Separation of ground loops between spatial circuits.

• Minimization of common- mode interference.

• Interference-free data transmission.

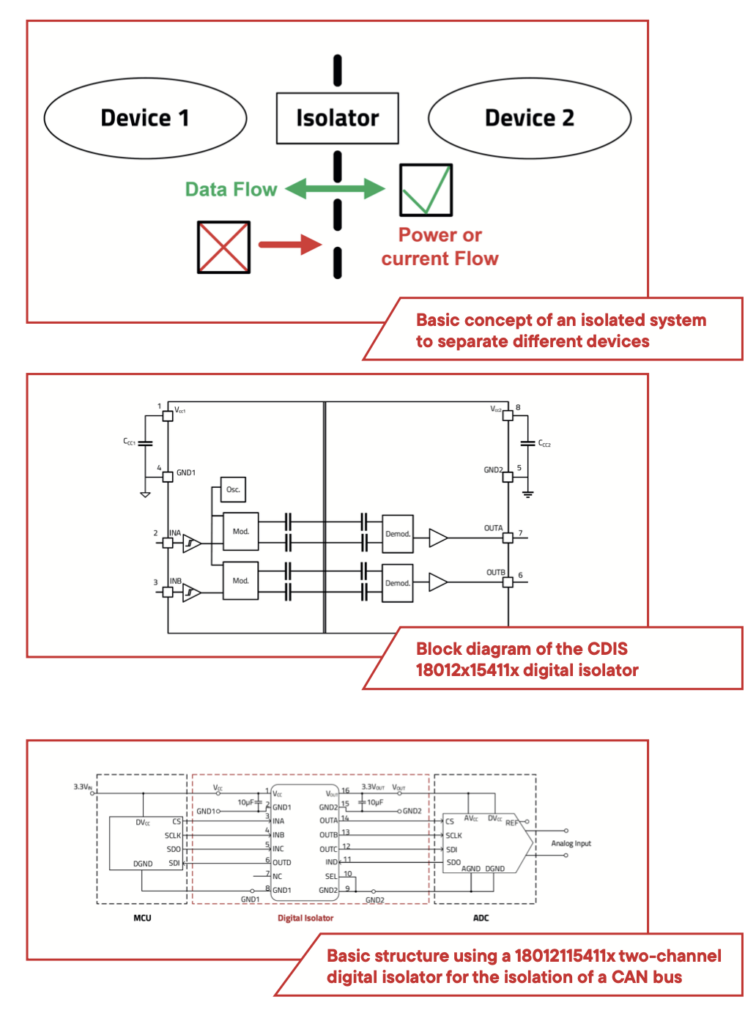

To meet the requirements of blocking dangerous voltages from the user while still guaranteeing interference- free data transmission, galvanic isolation must be used to split the zones electrically—that is, separate their potentials from each other—so that they can work independently and thus without interference.

To meet the requirements of blocking dangerous voltages from the user while still guaranteeing interference- free data transmission, galvanic isolation must be used to split the zones electrically—that is, separate their potentials from each other—so that they can work independently and thus without interference.

Würth Elektronik has recently launched a broad product portfolio of digital isolators that make it possible to cover a wide range of applications. All digital isolators are available with either default High or Low channel output versions.

Capacitive digital isolators

Digital isolators such as the 18012x15411x by Würth Elektronik consist of an oscillator and a modulator on the primary side. On the secondary side are a demodulator and a buffer. The primary-side components are galvanically separated from the secondary- side components by a capacitor structure with an isolation barrier made of silicon dioxide (SiO2).

Signal transmission through the isolation barrier is realized by a modulation method known as on/off keying. The oscillator integrated in the chip is used to modulate the Schmitt-triggered input signal. The modulator generates a differential signal that is transmitted via the capacitive insulation lines. The demodulator is located on the secondary side and is used to amplify, filter, and reconstruct the input signal. The signal delay and distortion are minimal. Finally, the signal from the output of the demodulator is passed through a buffer to the output; the buffer amplifies the

signal to the required level.

CAN bus application example

Digital isolators are placed between the CAN transceive and the local CAN controller, thereby allowing the system to be isolated from the lines. A single external isolated DC/ DC power module, such as the FIMM 1769205132, is required as a power supply for both the primary and the secondary side of the digital isolator, maintaining galvanic isolation with only one component. Würth Elektronik’s digital isolators can operate with a supply of 3.3V or 5V (i.e., both standard logic levels).

Digital isolators and isolated power supplies in combination eliminate ground loops and efficiently protect the system from damage due to overvoltage. More information about the two- and four-channel WPME-CDIS and WPME- CDIP series of digital isolators series can be found in datasheets on the Würth Elektronik website.