by Ralf Hickl, Product Sales Manager in the Automotive Business Unit (ABU) at Rutronik.

Battery monitoring is crucial for ensuring a reliable power supply for high-availability control units in assistance systems.

Parameters such as battery current and voltage are measured to monitor the battery in a vehicle. The electronics use these parameters to calculate the residual energy stored in the battery, among other variables. Based on this, a control unit can decide which loads may be switched on or must be switched off to ensure that vital assistance functions remain available. To measure the current, an important component in any battery sensor is the sensing element, such as shunt resistors.

The advantage of shunt resistors is that they provide a simple linear relationship between the measurand and the output signal. According to Ohm’s law, the voltage drop across the shunt is proportional to its constant resistance and the current flowing through it. This makes shunts suitable for DC and AC currents as well as for both current directions. The sensitivity to interference concerning temperature is known from the data sheet and can be calculated if the actual temperature value is known. One of the disadvantages is that the measurement signal of the shunt resistor—unlike current sensors based on the measurement of the magnetic field around a conductor—is at the potential of the current being measured. Therefore, current measurement in high-voltage systems still requires galvanic isolation of the measurement signal. In addition, shunts dissipate power loss according to the formula Ptot = R × I2, heat up, and transfer the heat to their surroundings.

Types of shunt resistors

Shunt resistors are available in various designs, depending on power and resistance; examples include thick film surface mount devices (SMDs) or metal surface mount resistors like the Vishay Power Metal Strip resistor. Compared to thick film resistors, metal resistors offer a higher pulse load capability.

Sizes for surface mount resistors range from 0603 to 5931. The higher the currents, the more the design changes toward metal brackets

with screw connectors.

The sensing element is made of a special alloy with the smallest possible temperature coefficient welded to two connecting elements made of copper. The position of the sensing taps is important: They should be as close as possible to the sensing element with the smallest possible current path in the copper to ensure the copper path with its higher temperature coefficient does not nullify the Wrende element and falsify the measurement result.

Tandem shunt from Vishay

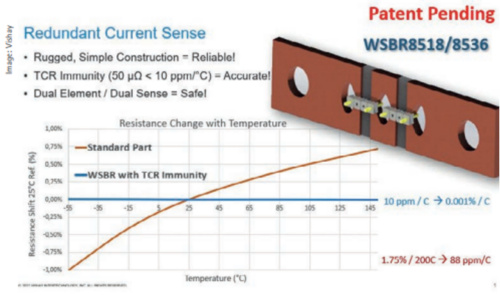

Automotive-qualified shunts with screw connectors and power loss up to 36W have long been offered by Vishay. These are the WSBS and WSMS series. Available are the low-inductance power metal strip versions with resistance values and temperature coefficients from 50μΩ and 10ppm respectively.

New to Vishay’s portfolio are the WSBE and WSBR series. The former extends the resistance range down to just 15μΩ while maintaining a low-temperature coefficient of up to ±10ppm and a small thermoelectric voltage of up to 1.25μV/°C. Since the power loss is proportional to the resistance of the shunt, the smaller resistance values of the WSBE shunts also allow higher currents to be measured.

The special feature of the new WSBR8518/8536 tandem shunt is its robust design with two independent measuring sections, which ensure high functional safety.

Verification is achieved by comparing voltage drops across these sections. In combination with appropriate evaluation electronics, applications with up to ASIL Dclassification can be achieved.