Today’s vehicles demand reliable, automotive-qualified timing devices.

Electronics has become a paramount and irreplaceable cog within the automotive industry’s wheel (pun intended). The use of electronics in vehicles produces more fuel-efficient or fuel-independent products, a more luxurious and interactive experience, and is also essential to ensuring a safer and more efficient mode of travel. More specifically, this is being accomplished with the implementation of infotainment and communication systems, advanced driver assistance (ADAS) and security systems, and body control and comfort systems. There is a never- ending and ever-growing list of components and modules designers utilize in the race to advance this sector. This article will highlight the necessity of incorporating reliable, automotive-qualified timing devices within the aforementioned systems.

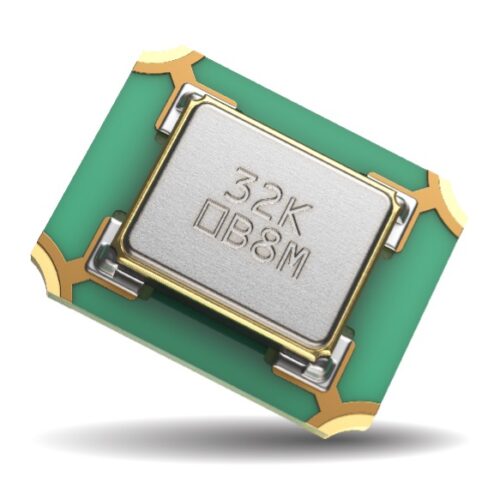

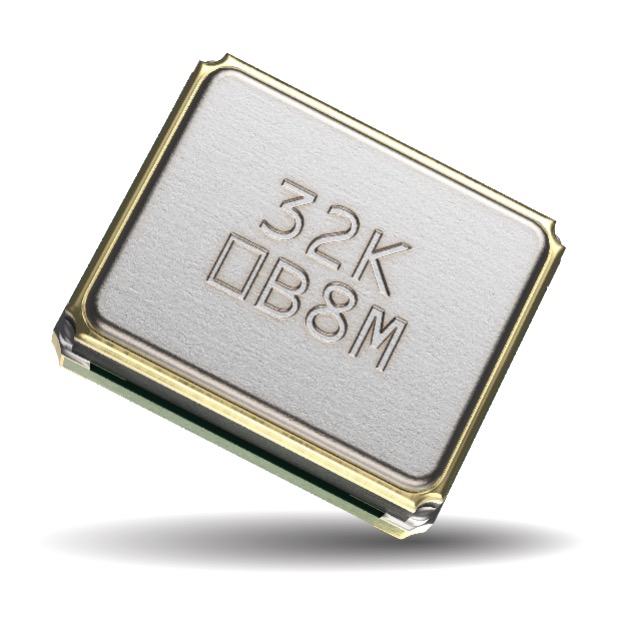

Before addressing the needs, advantages, and what to look for while implementing timing devices, discussing the inherent differences between a quartz crystal and a crystal oscillator would be prudent. A quartz crystal is a piezoelectric element that mechanically vibrates at a specific frequency when an alternating current (AC) signal is induced. A crystal, by itself, will not generate and maintain a steady and/ or strong enough signal to use as a reference clock or signal generator. This leads to the necessity of a crystal oscillator. Crystal oscillators are comprised of three main elements:

1. The crystal, which acts as the frequency- determining element.

2. The amplifier, which amplifies the signal generated by the crystal to a level suitable for the output device.

3. The feedback circuit, which is responsible for maintaining the oscillation of the crystal at its resonant frequency.

It is important to note that designers can employ a crystal and create the oscillator circuit themselves to “fine-tune” or optimize the device for a specific application. Typically, a crystal oscillator will save board space as it is built as a single compact design and alleviates the obligation of designing to certain parameters. ADAS and security systems are comprised of a wide array of networked sensors and technology to provide object or pedestrian warnings, real-time data, active braking, steering control, and blind spot detection, to name a few. Not only are crystal oscillators used in the composition of some of these sensors (e.g., ultrasonic sensors, image sensor processors, ABS braking), but they are also essential for the synchronization and frequency stability of the internal operation for the electronic control unit (ECU) of the vehicle. Crystal oscillators facilitate communication between the ECU and proximity/collision sensors, light detection and ranging (LiDAR) systems, global positioning systems (GPS), diagnostic interfaces, and battery management systems (BMS).

Another rapidly emerging application for timing devices is V2X communications, where vehicles communicate their position, trajectory, and conditions to infrastructure and other road users for increased safety and an improved transportation experience. All of these emerging applications rely on stable time bases to operate. The use of AEC-Q200 crystal oscillators is critical to guarantee that timing devices can generate and maintain stable and accurate frequencies over a long period of time and in highly variable temperatures. Constant vibration from either the engine’s operation or on-road driving can affect the accurate oscillation of the timing device. AEC-Q200 qualified timing devices are possible, with components from suppliers such as KYOCERA AVX. Having stable, refined, state-of-the-art manufacturing processes enables proven component designs that inherently reduce the effects of shock, vibration, and temperature extremes on the stability and longevity of their devices.