Current surge protection, voltage level translation, and debouncing—what’s not to love?

Deep in the mists of time when I wore a younger man’s clothes—circa the late 1970s—I was studying for my BSc degree in Control Engineering. This was a 4-year co-op course that commenced with nine months in college followed by six months in industry, and then do it all again. This was topped off by a final period of buffing and polishing at college, resulting in my emerging as a shiny new engineer.

My second stint in industry was at the research and development facility for a company called United Glass. Shortly before I arrived, someone had ordered a microcomputer based on the TMS9900 microprocessor from Texas Instruments (TI). The TMS9900 was one of the first commercially available, single-chip 16-bit microprocessors and it was awesome for its time. They told me to (a) learn how to use it and (b) think of things it could be used for. All I can say is that I was like a kid in a candy store.

After a couple of months at the R&D center, I was informed that I was being sent out into the field with my supervisor. We were to manage the installation of the new control systems in a glass factory that was in the process of being refurbished.

I don’t regret much in my life, but I do regret not spending more time learning about the 24V switching used in that glass factory. This voltage level is used for switches in myriad industrial settings. The main idea behind using 24V is that these signals are less affected by electromagnetic noise and IR-drop than are their logic-level (5.0V or 3.3V) counterparts. This is particularly important when you consider that the switches may be mounted remotely with long wires connecting them to the control system.

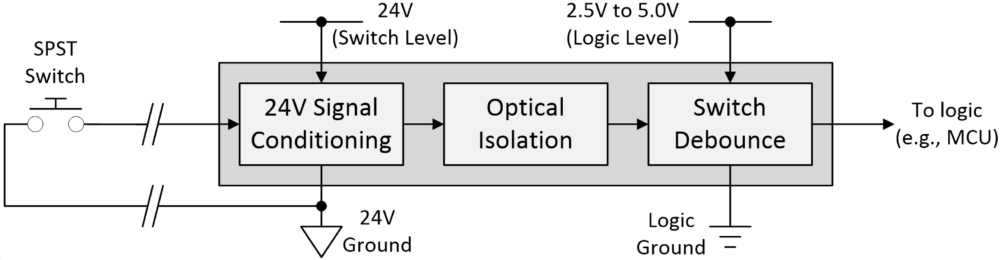

Speaking of which, when a 24V signal from a switch meets the control system, it must be passed through voltage-level-converter, after which it needs to be debounced. “Debounced?” you cry, “but isn’t that what you do?” Well, yes, as you so rightly observe, I am in fact the CTO for LogiSwitch. Switches bounce—that’s what they do. We have a family of small ICs that remove bounce—that’s what we do. Our chips come in 3-, 6-, and 9-channel flavors and in DIL or SMT packages.

The thing is that our ICs all work at logic-level voltages of 2.5 to 5.0V. Recently, I started thinking back to my student days in industry. In particular, I started to think that a small module, say around 0.75” by 1”, that could accept a 24V signal from a switch and transform this signal into a debounced logic level equivalent would be a jolly useful thing to have.

What we are talking here is opto-isolation. Surge protection of up to 40A along with overvoltage and undervoltage protection on the switch side, augmented with noise rejection and debouncing on the logic level side.

The problem is that I’m not sure exactly what industrial users most desire. Do they want to support voltages other than 24V? Is a single channel module sufficient or would multi-channel modules also be of interest? To satisfy our curiosity we’ve created a short survey (https://rb.gy/95e31). We really would be most appreciative if you could take a few moments of your time to tell us what you think.