Apex Microtechnology has developed techniques and products to ensure high reliability in high power situations.

Careful consideration of system reliability is essential when designing high-power analog components for aerospace and defense (A&D) applications. However, due to rigorous environmental conditions, device age, and modes of operation common in military systems, achieving both high power and high reliability can be a daunting task. Consequently, high power and high reliability often clash in A&D system designs.

Simultaneously achieving high power and high reliability in analog design is extremely difficult for several reasons. The primary concern being the increased impact of device parasitics; that is, unwanted intrinsic electrical elements.

Metal-oxide-semiconductor field-effect transistors (MOSFETS)—which are essential components in analog electronics—exhibit parasitics due to their device structure. Parasitic capacitances and resistances in MOSFETs result in unwanted power consumption during device operation, thereby reducing the reliability of the analog circuits.

Integrated circuits also experience parasitics at higher levels, including those from device packaging, bond wires, substrate layouts, and printed circuit board (PCB) layouts. While these parasitics are usually negligible in low-power applications, they become significant in high-power A&D applications due to the higher voltages and currents involved. This can lead to increased losses, thermal generation, and device temperature, making it difficult to achieve high reliability at high power.

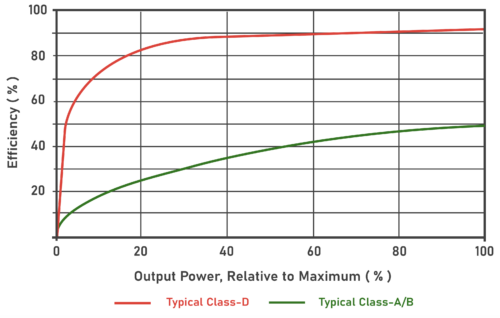

In aerospace and defense applications, specific architectural choices are necessary for high current and high voltage applications while still aiming for the highest possible reliability. For maximum efficiency in high power applications, design engineers often opt for class-D amplifiers. However, the tradeoff comes in the form of large amounts of electromagnetic interference from the surge currents (dl/dt) and peak voltages (dv/dt).

Large amounts of electromagnetic interference are unacceptable in A&D applications that require high sensitivity and accuracy, leading to the use of class-A/B amplifiers. While class-A/B amplifiers reduce electromagnetic interference, they come at the cost of efficiency, dropping from 90% range for class-D to approximately 50% range. Design engineers often need to compromise efficiency for the sake of minimizing electromagnetic interference and ensuring performance.

To combat these design challenges, Apex Microtechnology has developed several techniques and products to ensure high reliability in high power situations.

Silicon Carbide (SiC) MOSFETs

SiC—a wide bandgap semiconductor—offers reduced parasitics and a higher breakdown voltage than traditional silicon power FETs. SiC also offers superior thermal performance and reliability in high-power applications. Apex offers a product portfolio of integrated power modules, such as the SA111, SA310, and SA110 that incorporate Silicon Carbide technology to expand the boundaries of thermal efficiency and power density in analog design.

Packaging techniques

Apex ensures high reliability at high-power through rigid device packaging, utilizing base plates made from thermally conductive materials and pressure-sintered die attaches that ensures minimal voiding and thus greater thermal conductivity between substrate and base plates.

Through both techniques, Apex designs their amplifiers to sink heat away from the components, which lengthens device lifetimes and ensures proper operation, even in rigorous operating environments. In these ways and many more, Apex ensures its customers can balance the tradeoffs between high power and high reliability.