Voltage regulation subsystems are required throughout vehicles.

Modern vehicles contain myriad subsystems that require local voltage regulation tailored to their specific application. These subsystems are found throughout the vehicle. They can range from high power active functions like headlights and climate control to low power passive modules such as keyless entry and tire pressure monitoring.

Each of these subsystems is designed to function under specific environmental limits within the greater automotive AEC-Q100 umbrella. Some are constrained by the available physical space, while others are designed with a focus on performance and efficiency. For DC/DC converters specifically, these unique requirements may include tolerance to wide swings in battery bus voltage, higher primary input voltages up to and including 60VDC, limitations on physical space available for supporting passives, and high conversion efficiencies under light loads and wide input/output ratios. To achieve these goals, ROHM has introduced two proprietary technologies into its DC/DC lineup specifically tailored to automotive needs: Nano Pulse Control and QuiCur.

Nano Pulse Control technology

Nano Pulse Control is a DC/DC switching technology that offers the industry’s smallest pulse width of only 9 nanoseconds. This is nearly 14X faster than a conventional converter.

This miniscule pulse width allows ROHM’s DC/DC converters to handle large input to output ratios, which makes them ideal for higher automotive bus voltages. Nano Pulse Control allows these converters to directly buck a 48V input rail down to a 1V output rail in a single stage. Competitor products, on the other hand, require an intermediate step utilizing two separate conversion integrated circuits (ICs). From a cost and space perspective, Nano Pulse Control is a clear industry leader that offers advantages in terms of efficiency and simplicity.

QuiCur technology

Integrated in ROHM’s DC/DC and low dropout regulator (LDO) product lines, QuiCur technology is a circuit level technique that solves several of the main problems plaguing the feedback networks used to achieve high performance frequency response. This technology relies on introducing two dedicated error amplifiers into the feedback path. The second stage plays a particularly critical role by scaling its gain by the overall drive current. The result is a much more flexible frequency response tradeoff, allowing the designer to choose between optimal stability, minimal undershoot, and reduced physical size.

For a given circuit design, using QuiCur immediately improves responses to rapid changes in load current. The voltage variability of the system is much lower when a sudden increase in load is encountered. This opens up the opportunity for a designer to use a smaller output capacitor without worrying about potential oscillation issues. The result is a high-performance regulator that is both smaller and more cost effective.

Primary DC/DC converter example

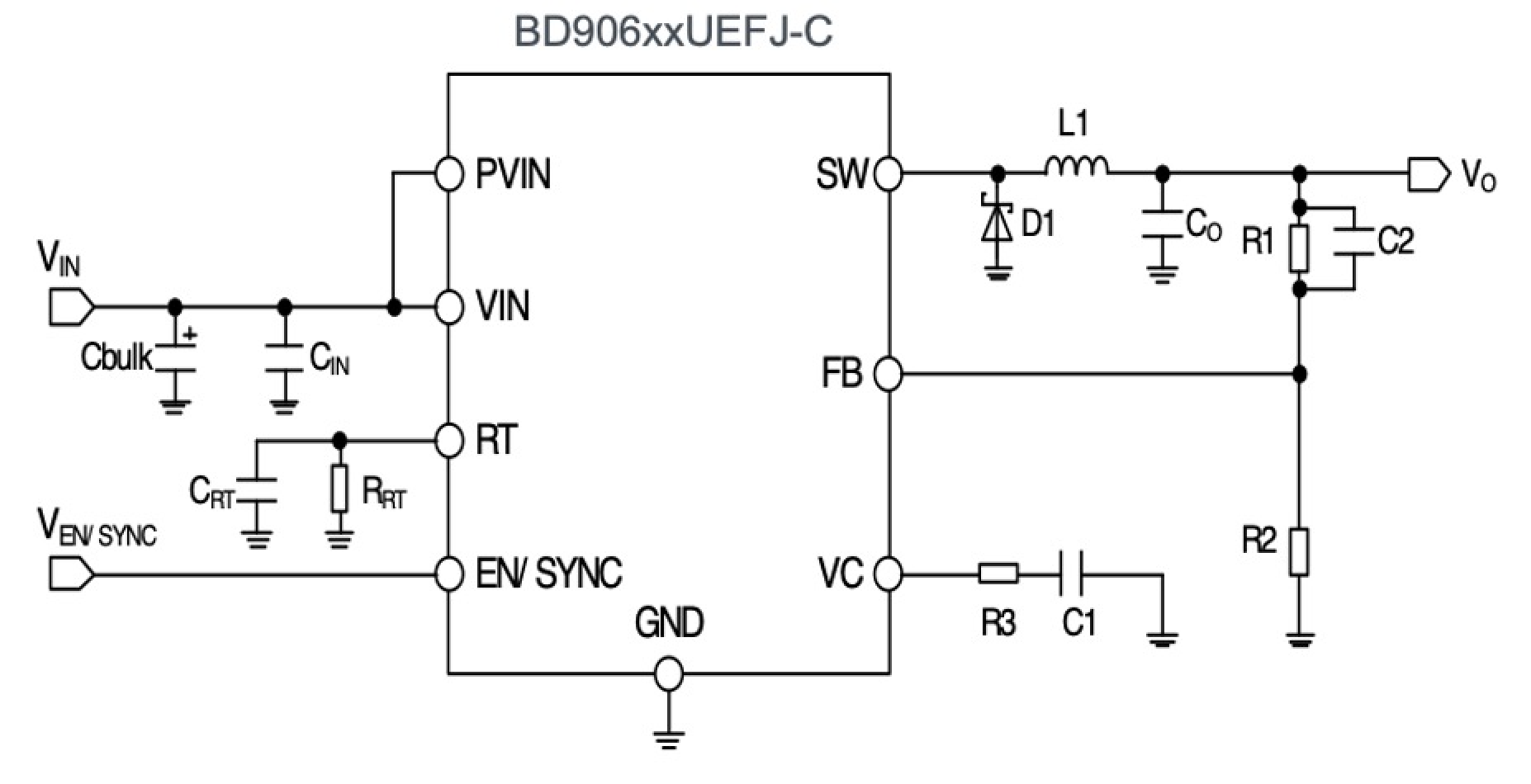

To illustrate the simplicity and rich feature set of ROHM’s family of DC/DC converters, an example is shown for the BD906xx series, where the high voltage battery bus must be switched down to a much lower supply rail for an automotive infotainment system. This circuit can accept anywhere from 3.5V to 36V on the input side and—in a single stage—provide a regulated output down to 0.8V.

This regulator can supply up to 4.0A of current through the integrated output switch with an adjustable switching frequency between 50-600kHz. Available in a compact HTSOP package measuring just 4.9mm × 6.0mm × 1.0mm, the series is fully AEC-Q100 qualified and requires only a handful of supporting passive components.

Secondary DC/DC converter example

As is often the case, secondary supply rails must also be regulated down to lower voltages. In conventional technologies, two separate converters are usually chained in series to achieve the desired current rating while maintaining efficiency during light load operation. ROHM’s Nano Pulse Control technology can accomplish this in a single stage with very few supporting components.

For example, using a BD9Sx00 series DC/DC converter to step a 5V rail down to a 0.8V core supply for an engine control unit (ECU). This device can provide up to 4.0A of current with integrated switches operating at 2.2MHz.

The BD9Sx00 also features a “power good” signal and adjustable soft functionality that can be paired with a selectable light load mode. Available in a compact VQFN package of only 3.0mm × 3.0mm × 1.0mm, these DC/DC converters provide best-in-class performance for a wide range of secondary supply regulation demands.

Conclusions

Automotive electronic requirements present a unique set of environmental constraints that apply to a wide variety of voltage regulation solutions. Foremost among these are high input voltage combined with volumetric efficiency.

ROHM’s proprietary Nano Pulse Control and QuiCur technologies enable DC/DC converters to thrive under these environments. They provide large input to output ratios, high performance frequency response, and an overall reduction in physical volume and supporting componentry. What’s more, AEC-Q100 qualification makes these devices perfectly suited to the design requirements of many vehicle subsystems.