These devices provide an added design option for next-generation aerospace applications.

Aerospace is becoming an increasingly active marketplace, especially the overall satellite sector with market growth projections increasing from ~$6 billion USD in 2023 to $9.6 billion USD by 2030 (Grandview Research). Whether it be low-earth orbit (LEO), medium-earth orbit (MEO), or high earth orbit (HEO), the advances in satellite performance have been driven by active electronic components such as microcontrollers, FPGAs, and processing cores. With the rapid and continuous progression of ICs (integrated circuits), the limiting factor to system performance is the passive components surrounding them.

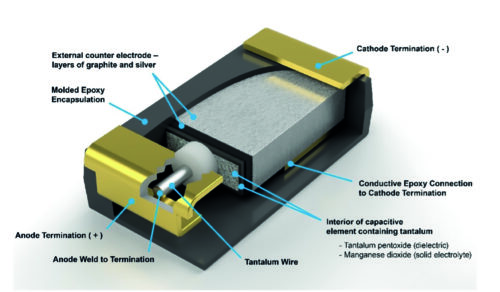

Power management innovations have played a critical role in these advancements as the complexity of the ICs becomes more prevalent. To add to the complexity, the power quality must also be consistent when raw power is obtained from solar panels or batteries. Size and weight, as in all aerospace applications, play a massive role in deciding which components will go into the circuitry of satellites. Solid tantalum capacitors have been used as bulk capacitors in aerospace applications for the past two decades with extremely positive results. However, to keep up with the higher voltage stability and capacitance ranges of next-generation ICs, the implementation of tantalum polymer capacitors is a welcomed added design option.

Tantalum polymers offer reduced equivalent series resistance (ESR) and, therefore, higher RMS current capability associated with cutting-edge flight platforms. Both tantalum capacitor technologies will be utilized in next-generation advanced flight platforms in areas where they individually excel regardless of orbit characteristics.

Within the satellite/aerospace marketplace, there are two main business sectors: military and commercial. The former are expected to need high-reliability tantalum and hermetically sealed tantalum polymer capacitors, while the latter will most likely go for the molded options for cost-restrained and quick-turn designs. There is a space and military performance standard being created, MIL-PRF-32700, for tantalum polymer capacitors, indicating interest in documented reliability from end customers.

The construction of hermetic tantalum capacitors should be reviewed given recent agency interest, testing and flight acceptance. Hermetic tantalum polymers use polymer cathodes, which are moisture sensitive, but this sensitivity is eliminated by encapsulating the anode in a hermetic package filled with an inert gas. An example of a hermetic tantalum polymer option is the KYOCERA AVX TCH series.

Molded tantalum polymer capacitors also exist, and their performance has been greatly improved by rigorous testing and modernized engineering processes. This work has pinpointed moisture ingress areas and resulted in the addition of moisture barriers to create a molded package that is as close to hermetic as possible while reducing the cost associated with wholly hermetic options. An example of the molded option is the KYOCERA AVX TCS series. Conductive polymer stability throughout thermal cycling and low ESR makes them an ideal choice for high-power filtering. High altitude, low/high pressure, vacuum, and radiation have minimal impact on the functionality of conductive polymer capacitors, making them ideal solutions for aerospace applications.

Mesh satellites, swarm satellites, cube satellites, telecommunication satellites, and reconnaissance satellites are all just the tip of the iceberg when it comes to next-generation aerospace technology. With the active electronics contained in these satellites constantly pushing the boundaries of existing passive components, there will be a huge demand for small, lightweight, reliable bulk capacitors. Tantalum polymer devices like the ones discussed here are an example that the passive components industry is aware of—and proactively providing solutions for—commercial to mission-critical space and flight applications.